February 22 – Ontario Power Generation (OPG) last month abandoned plans to close the remaining six reactors at its Pickering Nuclear Power Station, opting instead to refurbish four of the units (Pickering B Units 5-8) starting in 2027. Units 1 and 4 will close at the end of this year.

February 22 – Ontario Power Generation (OPG) last month abandoned plans to close the remaining six reactors at its Pickering Nuclear Power Station, opting instead to refurbish four of the units (Pickering B Units 5-8) starting in 2027. Units 1 and 4 will close at the end of this year.

The decision will grant the four 515 MW Canada Deuterium Uranium (CANDU) reactors, built in the seventies and eighties and generating 14% of the province’s electricity, opens new tab, at least another 30 years of life.

“Ontario is already home to one of the cleanest electricity grids in the world and one of the most resilient in large part thanks to the diversity of our energy supply,” Ontario’s Energy Minister Todd Smith said during the Pickering announcement while standing in front of the plant and dozens of union workers.

“Under our plan to power Ontario’s growth, we’ve taken a pragmatic approach that leverages every part of our energy sector to support our growth … But it’s our nuclear stations like the Pickering Nuclear Generation Station behind me that are the workhorses of our grid.”

Despite its age, the plant recorded its second highest generation output as a six-unit station in 2023. In 2022 all six operating units ran simultaneously for 109 consecutive days, a station record.

Extending the life, opens new tab of existing nuclear plants is the most cost-effective source of low carbon electricity, according to a study, opens new tab of 243 plants across 24 countries conducted by International Energy Agency (IAE) and the OECD Nuclear Energy Agency (NEA).

Provincial boost

The refurbishment will increase Ontario’s GDP by CAN$19.4 billion ($14.4 billion) over the 11-year project period and create about 11,000 jobs per year, according to the Conference Board of Canada.

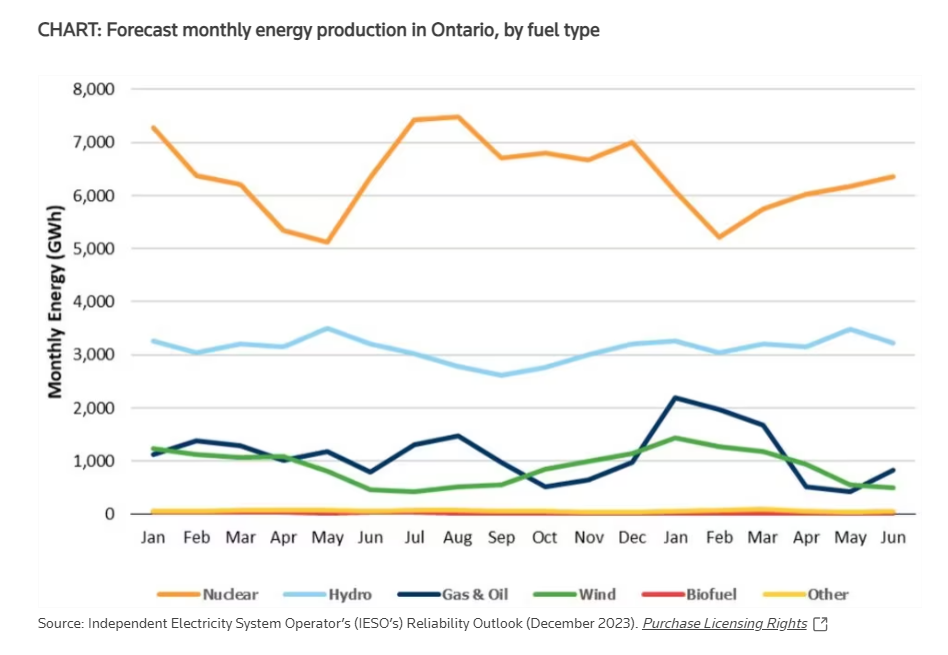

Ontario must double the size of its nuclear capacity over the next 26 years to meet its electrification goals and reduce its dependency on fossil fuels, according to the Ontario public grid operator Independent Electricity System Operator’s (IESO’s) 2050 decarbonized scenario.

That means adding an additional 17.8 GW of nuclear power in just less than three decades.

“If we want to get off natural gas, nuclear must be part of the mix. There is no other way to get there,” says Subo Sinnathamby, Senior Vice President of Nuclear Refurbishment at OPG.

Sinnathamby is already overseeing the four-unit refurbishment at OPG’s Darlington nuclear power station which is on budget and on schedule to be completed by 2027.

Bruce Power, opens new tab is also extending the life of its 6.5 GW nuclear plant further north through a major component replacement (MCR) program. The Darlington and Bruce Power projects have helped fortify nuclear power supply chains and feed an expanding pool of highly qualified workers.

“We’ve had a very mature, strong supply chain that has just benefited and been strengthened as we executed the Darlington refurbishment, and the reason that was strengthened was our multi-unit procurement strategy,” says Sinnathamby.

Procurement orders for the four Darlington units were placed early to ensure companies were prepared in advance.

“When we did that, that gave the vendors that were providing us with the components that we needed the confidence to go ahead and build their shops, build a capability, and have a production line ready to go to support us.”

The same model will be applied at Pickering, she says.

“The Darlington refurbishment will be finished by end of 2026 and, pending regulatory approval, we’re shutting down Pickering at the same time. We’ll have the transition of a skilled workforce that knows how to do refurbishment. The supply chain is mature. Our vendor community is mature. We really positioned ourselves well to leverage everything that we’ve got today.”

CANDU attitude

As the original equipment manufacturer (OEM) of CANDU reactors, opens new tab, AtkinsRealis has a history of refurbishing CANDU plants, having worked on Darlington and Bruce Power Nuclear Generating Station, New Brunswick’s Point Lepreau, Romania’s Cernavoda, South Korea’s Wolsong, China’s Qinshan, and Argentina’s Embalse. AtkinsRealis was previously known as SNC-Lavalin.

The CANDU design is especially suitable for refurbishment, as the pressure tubes in the reactor can be individually replaced and fuel channels can be accessed without the need to decommission the entire reactor.

“The design of the CANDU reactor is substantially different than the design of any other pressurized reactor and makes it especially refurbishment capable,” says Gary Rose, Executive Vice-President of Nuclear at AtkinsRealis.

In the CANDU design, the containment vessel remains at low pressures, reducing the stress on the reactor components, while the fuel channels are pressurized.

By replacing those fuel channels and the feeder pipes, the reactor can run for another 30 years, Rose says.

“It’s like we’ve replaced the engine in a really good car. You can get another 300,000 km out of it.”

Ahead of the latest iteration on the design, the 1 GW CANDU MONARK reactor, opens new tab which is currently in the definition phase, AtkinsRealis is looking at whether such reactors can be refurbished more than once.

“We have yet to refurbish a CANDU reactor a second time, which would bring it to over 100 years of operation, but that question is being asked and we will, in time, answer that,” says Rose.

Factors such as developing local energy needs and the economics of doing the refurbishment play a part in whether a reactor will be refurbished or not.

“Economically, it’s more certain because we’ve done so many of them that we’re getting pretty good at it,” he says.

“In a world where we’re trying to maximize the fossil free energy that’s available to us, refurbishing of reactors is the cheapest, most viable, and quickest option.”

Source: REUTERS